Publisher: Administrator Date:2023-11-23

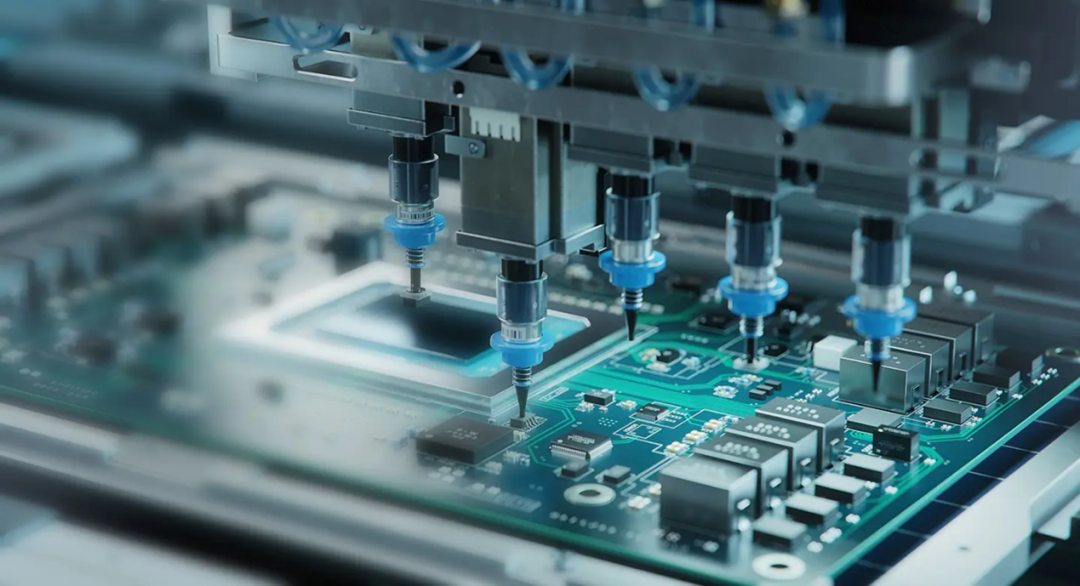

Teknek provides a revolutionary contact cleaning

solution for SMT surface mounting technology

As electronic products tend towards miniaturization and high integration, traditional integrated circuits can no longer meet the requirements, giving rise to SMT (Surface Mount Technology). The advantages of SMT component assembly processing include: high assembly density, smaller electronic product size, lighter weight, with the volume and weight of the SMT components being only about 1/10 of those of traditional through-hole components. They also offer high reliability, strong vibration resistance, and low defect rates in solder joints. Moreover, SMT has good high-frequency characteristics, reducing electromagnetic and radio frequency interference. It is easy to automate, which increases production efficiency and can reduce costs by 30% to 50%.

After laser marking or before solder paste printing.

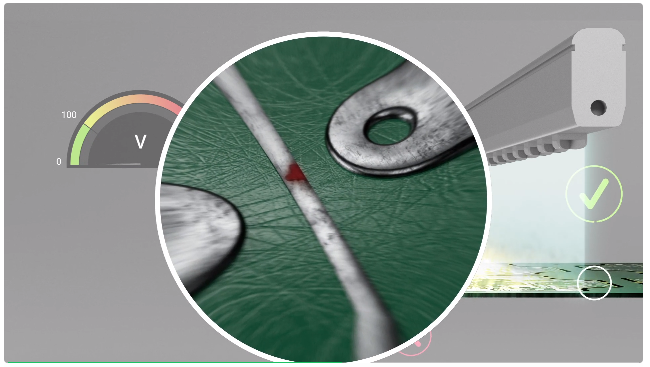

SMT technology is a circuit connection technology that installs leadless or short-lead surface-mounted components on the substrate surface of a circuit board, and assembles them by methods such as reflow soldering or wave soldering. The welding assembly process generates solder paste residues, fine metal particles, and dust. Highly integrated and small-sized printed circuit boards are extremely susceptible to contamination, which can lead to performance degradation or failure. Therefore, before solder paste printing, manufacturers will use contact cleaners to clean, which can effectively remove particles and prevent blockages in the printing steel plate, ensuring the quality of solder paste printing. Teknek contact cleaners, with advanced contact cleaning technology and specially developed adhesive materials, can efficiently adsorb and remove tiny particles and contaminants on the surface of the circuit board, making them the preferred choice for many manufacturers.

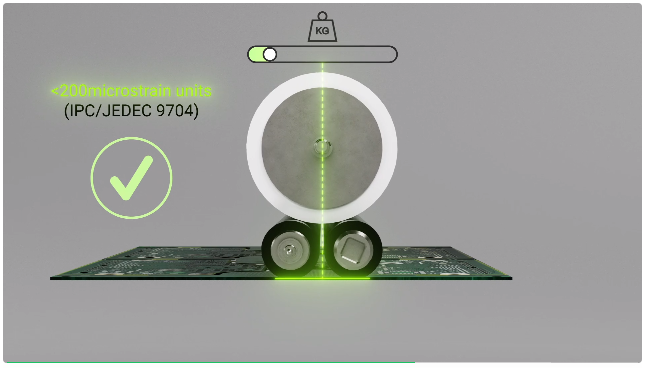

Industry 4.0 has arrived, bringing with it Teknek's revolutionary Tek-BC series of PCB cleaners. This versatile product represents the future trend of "low static-low stress"PCB cleaning in today's SMT industry. The Teknek 2.0 philosophy drives the development of this breakthrough product,which offers more than just a routine cleaning process.

The Tek-BC series products use independently developed, forward-looking elastic dust-collecting adhesive roller to remove residues from printed circuit boards, such as board debris, hair, or other loose particles. At the same time, they utilize the industry's highest standard static 20.20 technology to eliminate static electricity, thereby providing exceptional performance. This not only reduces the stress on components during the assembly process but also ensures that components meet very high cleaning standards before soldering. The Tek-BC series products are compatible with Industry 4.0 technology and can be quickly and easily integrated into existing production lines without affecting production time or causing delays.

The products in this series also feature a variety of functions, including user-friendly operation software, excellent cleaning results, and quick conversion times between different machine types. Additionally, there is no need to purchase extra tools or instruments, as each model in the Tek-BC series includes everything required. Furthermore, since each model can be optionally equipped with a complete traceable data recording function, users can easily and accurately review past cleaning situations in case any issues arise in the future.

As an innovative British supplier of contact cleaning solutions, Teknek independently develops forward-looking contact cleaning products, providing flexible and effective contact cleaning solutions for customers worldwide. Teknek has earned the trust of many well-known clients, such as Tesla, Huawei, Panasonic, and more. Currently, over 29,000 cleaning devices are operating in various industries globally, tirelessly helping customers worldwide achieve zero-defect and zero-contamination production. Should you have any questions regarding contact cleaning, please feel free to contact our professional contact cleaning team at any time.。

About Teknek

Teknek is headquartered in Scotland, UK, and for over 35 years has been dedicated to the research and development of contact cleaning equipment. Adhering to the philosophy of zero pollution in the manufacturing process, their products have achieved ISO 9000:2015 certification. Today, Teknek has become a leader in the world of contact cleaning for sheet materials and web materials.