Publisher: Administrator Date:2021-02-04

As a professional manufacturer and supplier of welding equipment and tools, ESAMBER provides complete electronic assembly welding solutions for users worldwide. Among them, ERSA's Hotflow 3 series reflow ovens are top-notch reflow soldering equipment developed for lead-free applications and high-volume requirements. They incorporate several patented technologies and possess many unique technical advantages that are "unique to us when others don't have it, and superior to others when they do."

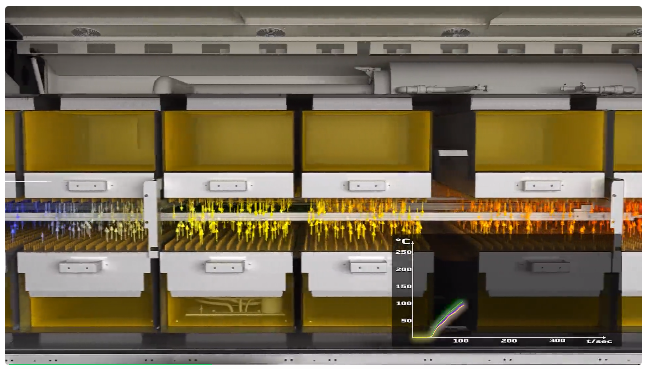

The unique multi-nozzle design increases heat transfer efficiency, prevents displacement of small components, and eliminates cross-contamination of temperatures between adjacent zones.

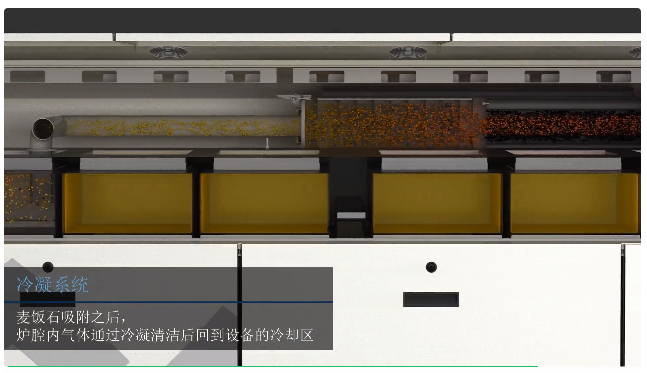

The unique macaune (a type of zeolite) condensation and adsorption process decomposes flux residues, significantly enhancing the equipment's flux management capabilities.

The Hotflow 3 helps customers achieve their dream of perfect reflow soldering with its capabilities.

1.Powerful heat transfer and thermal recovery capabilities easily handle the soldering of large heat capacity circuit boards.

2. Powerful cooling capabilities, with multiple cooling configurations available to meet different cooling requirements.

3. Minimized lateral temperature differences fully satisfy the reflow soldering of high-difficulty complex circuit boards.

4. With up to 13 heating zones + 4 cooling zones, from dual-lane to quad-lane, it meets the demands of ultra-high production capacity.

5. Ultra-energy-saving design - You are welcome to measure the power consumption and nitrogen consumption of ESAMBER reflow ovens on-site.

6. The full-track vibration-free design eliminates disturbances to the solder joints, ensuring welding quality.

7. The parallelism deviation of the track is within 1mm throughout its entire length, preventing board jamming and dropping.

8. Furnace temperature curve simulation generation software meets the requirements for furnace temperature adjustment in the case of multi-variety/ small batch production.

9. The heating and cooling modules feature a slide-out design, allowing one person to handle equipment maintenance and servicing.

10. HERMES communication, MES connection, real-time monitoring of furnace temperature - we have everything you need.