Publisher: Administrator Date:2022-02-17

Perfect semiconductor soldering with Ersa's patented technology

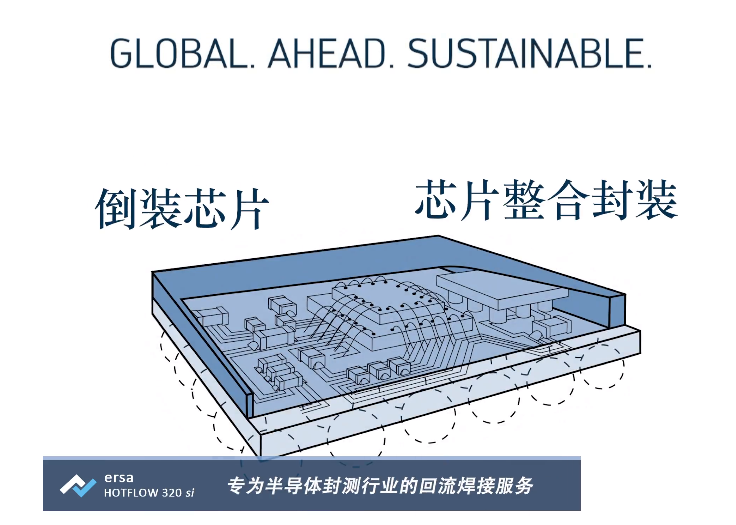

As a professional supplier of soldering equipment and tools, Ersa is committed to providing comprehensive electronic assembly production solutions to Chinese customers. The Hotflow 3 series, which is widely praised by customers, has several patented technologies to match the high quality and high mass requirements. The Hotflow 3/20 si, which is also part of the reflow series, is a leading product of soldering equipment for the semiconductor industry with clean room soldering standard, cooling ramp rate of 0.2-3 degrees/sec, closed-loop control of residual oxygen below 20 PPM, special mesh conveyor configuration for semiconductors.

The core components of the reflow oven, which are the key to the quality of the equipment, are imported for the Hotflow 3/20 si, and are equipped with motors made in Germany and advanced sealing to meet the demand of clean room production environment. In order to achieve a stable process and improve the reliability of the Hotflow si, this reflow oven uses high-quality German imported conveyor rails and specially designed mesh conveyor for semiconductor soldering, so that the rails are vibration-free and prevent the creation of overstressed solder joints. In addition, the optional Ersa patented Smart Elements™® flux residue management method makes the process of handling solder paste residue safer and enhances the efficiency of the equipment.

Hotflow 3/20 si fully matched to the soldering needs of semiconductor industry:

2. Special mesh conveyor for semiconductors

3.Nitrogen injection in every heating zone, residual oxygen less than 20ppm with more than 3 measuring points

4. 14 independently temperature zones for advanced reflow temperature profile

5. Enhanced process tunnel with advanced sealing

6. Cooling slope up to 0.2~3℃/s

7. ESD according to industry standard

8.Multiple special designs to ensure that it meets the requirements of clean room levels